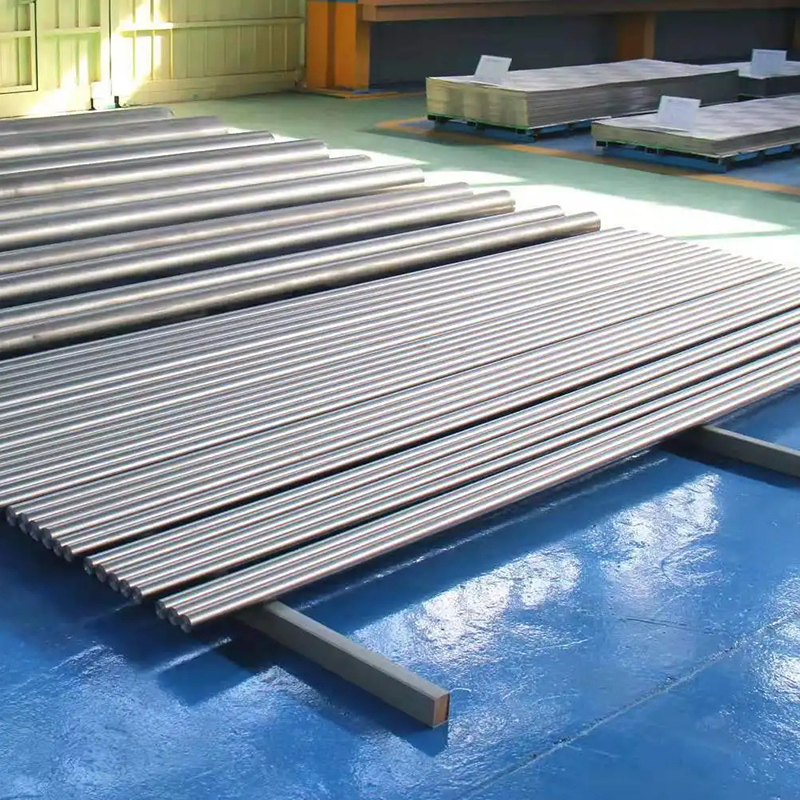

S32205/ S31803 Ishubhu, Ipuleti, Ibha

Imikhiqizo Etholakalayo

Ishubhu elingenamthungo, Ipuleti, Induku, Iziqashi, Izixhumi, Izifakelo zamapayipi.

Amazinga Okukhiqiza

| Umkhiqizo | I-ASTM |

| Amabha, amapheshana namaphrofayili | A276, A484 |

| Ipuleti, Ishidi kanye Nomdweshu | A240, A480 |

| Amapayipi Angenamthungo futhi Ashiselwe | A 790, A 999 |

| Ukufakwa Kwepayipi Elingenamthungo futhi Elishiselwe | A 789, A 1016 |

| Ukufakwa | A815, A960 |

| Ama-flange amapayipi afojiwe noma agingqelwe kanye nokufakwa komgunyathi | A182, A961 |

| Ukuqamba amabhilidi namabhilidi | A314, A484 |

Ukwakheka Kwamakhemikhali

| % | Fe | Cr | Ni | Mo | C | Mn | Si | P | S | N |

| Okuncane | Ibhalansi | 22.0 | 4.5 | 3.0 | 0.14 | |||||

| Ubukhulu | 23.0 | 6.5 | 3.5 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 0.20 |

Izakhiwo Zomzimba

| Ukuminyana | 7.69 g/cm3 |

| Iyancibilika | 1385-1443 ℃ |

Izinto ezibonakalayo ze-S32205

I-ASTM A240/A240M--01 Duplex insimbi engagqwali 2205 ingxubevange iyiduplex insimbi engagqwali eyakhiwe 22% chromium, 2.5% molybdenum kanye 4.5% nickel-nitrogen alloy.Inamandla aphezulu, ukuqina komthelela omuhle kanye nokumelana nokugqwala okuhle kwengcindezi yendawo yonke.Amandla okukhiqiza angu-2205 ensimbi engagqwali eyi-duplex angaphezu kokuphindwe kabili kwensimbi evamile ye-austenitic.Lesi sici sivumela abaklami ukuthi behlise isisindo lapho beklama imikhiqizo, okwenza le ngxube ithengeke kakhulu kuno-316 no-317L.Le alloy ifaneleka ikakhulukazi ukusetshenziswa ebangeni lokushisa elingu-50°F/+600°F.Kuzinhlelo zokusebenza ezingaphandle kwalolu banga lokushisa, le alloy nayo ingacatshangelwa, kodwa kunemikhawulo ethile, ikakhulukazi uma isetshenziselwa izakhiwo ezishiselwe.

Izinzuzo ze-S32205 Duplex Steel

1.Amandla esivuno angaphezu kokuphindwe kabili kwensimbi engagqwali ye-austenitic ejwayelekile, futhi inezidingo zokwakheka ezidingekayo.

Ipulasitiki eyanele.Ukuqina kodonga lwamathangi okugcina noma imikhumbi yokucindezela eyenziwe ngensimbi engagqwali eyi-duplex iphansi ngo-30-50% kunaleyo ye-austenite evame ukusetshenziswa, evumela ukwehlisa izindleko.

I-2.Inokumelana okuhle kakhulu nokucindezeleka kokuqhekeka kokugqwala.Ngisho nensimbi engagqwali eyi-duplex enokuqukethwe kwe-alloy ephansi kakhulu inokumelana okuphezulu nokucindezela kokuqhekeka kokugqwala kune-austenitic stainless steel, ikakhulukazi endaweni equkethe ama-ion e-chloride.I-stress corrosion inkinga evelele insimbi engagqwali ye-austenitic okunzima ukuyixazulula.

3.Ukumelana nokugqwala kwensimbi engagqwali eyi-2205 esetshenziswa kakhulu emithonjeni eminingi yezindaba ingcono kuneyensimbi engagqwali engu-316L austenitic ejwayelekile, kuyilapho i-super duplex insimbi engagqwali inokumelana nokugqwala okuphezulu kakhulu, futhi kweminye imidiya, njenge-acetic acid, i-formic acid Ingakwazi ngisho nokuthatha indawo yensimbi engagqwali ene-alloy austenitic, ngisho nama-alloys amelana nokugqwala.

4. Inokumelana nokugqwala okuhle kwendawo.Uma kuqhathaniswa nensimbi engagqwali ye-austenitic enokuqukethwe kwe-alloy okulingana, ukumelana kwayo nokugqwala nokukhathala ukumelana nokugqwala kungcono kunensimbi engagqwali ye-austenitic.

5. I-coefficient yokunwetshwa komugqa iphansi kunaleyo ye-austenitic stainless steel, eseduze naleyo ye-carbon steel.Ifanele ukuxhuma nge-carbon steel futhi inokubaluleka okubalulekile kobunjiniyela, njengokukhiqizwa kwamapuleti ahlanganisiwe noma ama-linings.

6. Kungakhathaliseki ukuthi ingaphansi komthwalo oguqukayo noma izimo zomthwalo omile, inamandla okumunca amandla aphezulu kunensimbi engagqwali ye-austenitic, enezinzuzo ezisobala zezingxenye zesakhiwo ukuze zibhekane nezingozi ezingazelelwe njengokushayisana, ukuqhuma, njll., futhi inenani elisebenzayo lohlelo lokusebenza.

I-S32205 Material Application Areas

Imikhumbi yokucindezela, amathangi okugcina ingcindezi ephezulu, amapayipi okucindezela okukhulu, ama-heat exchangers (imboni yokucubungula amakhemikhali).

1.Amapayipi kawoyela negesi, ukufakwa komshini wokushisa.

2.Isistimu yokuhlanza indle.

3.Izihlukanisi zemboni ye-Pulp nephepha, izitshalo zokuxubha, ukugcinwa kanye nezinhlelo zokwelapha.

4.Ama-Rotary shafts, ama-press rolls, ama-blades, ama-impeller, njll. endaweni enamandla amakhulu kanye ne-corrosion resistant.

Amabhokisi we-5.Cargo wemikhumbi noma amaloli

6.Imishini yokucubungula ukudla